Did you know that buildings with metal frames began in the late 1700s? If you are trying to learn a little more about metal, you are in the right place. There are plenty of people that use the words metal fabrication and welding interchangeable but they truly aren’t.

Although they both deal with metal they are not the same thing. Keep reading to learn more about the ins and outs of welding and metal fabrication.

Metal Fabrication

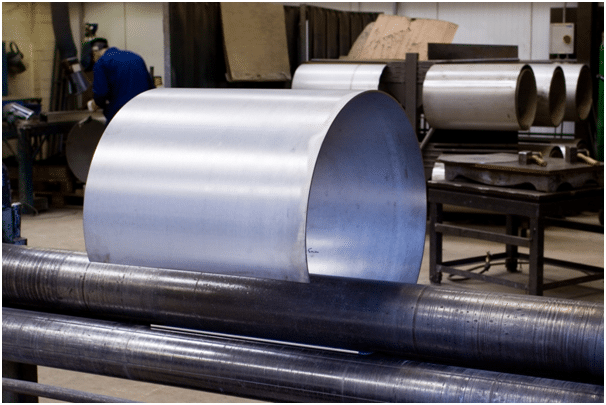

Metal Fabricators deal with metal just like welders do but, they do a little bit of everything. They cut, bend, and assemble metal parts together. The exact method used during fabrication will completely depend on what the project calls for.

This is considered the overarching process which involves a bunch of different processes like die-cutting, spinning, shrinking, roll forming, finishing, stretching, etc.

Welding

Welding is a process that only requires one task vs metal fabrication. A welder joins two pieces of metal together with special equipment and he or she can become an expert using their equipment to the point that they can weld pretty much any task handed to them.

There are different ways to weld, including GMAW (Gas Metal Arc), TIG, and Oxy-Acetylene. Keep in mind that both metal fabrication and welding use assembling and bending in order to reach their final product.

Tools

One of the major differences in the tools that are used. Metal fabricators use tools that deal with cutting metal, machining, and also bending. The metal fabrication process usually starts with cutting metal sheets into the size requirement.

The tools for a fabricator include plasma torches, laser cutters, and mechanical saws. They also use a tool called a lathe in order to remove portions of the metal to create things like holes.

Welders, on the other hand, use welding clamps, torches, benders, soapstone, consumable electrodes, and power sources just to name a few. Most tools that are used by fabricators can’t be used for welding because they need more specific instruments.

Safety

Whether someone does welding or metal fabrication it is a dangerous industry because they both work with hot metal and heavy machines. Every welder and metal fabricator should be aware of all of the safety guidelines in their line of business.

When working every tradesperson should have things such as fume extraction equipment, flame resistant pants, coveralls, steel toe boots, safety goggles, hearing protection, respirators, etc. When working for a company there should be strict training to make sure everyone is safe.

Feeling Like a Metal Fabrication vs Welding Pro?

We hope that now that we cleared up the differences between welding and metal fabrication, you do not use the terms interchangeably. In today’s modern world you see metal pretty much everywhere from the vehicles we drive every day to skyscrapers to industrial plants.

Found our blog post informative? Browse the rest of this section to catch more of our latest.